Steps to Diagnose a Malfunctioning Heat Pump Component

Table Of Contents

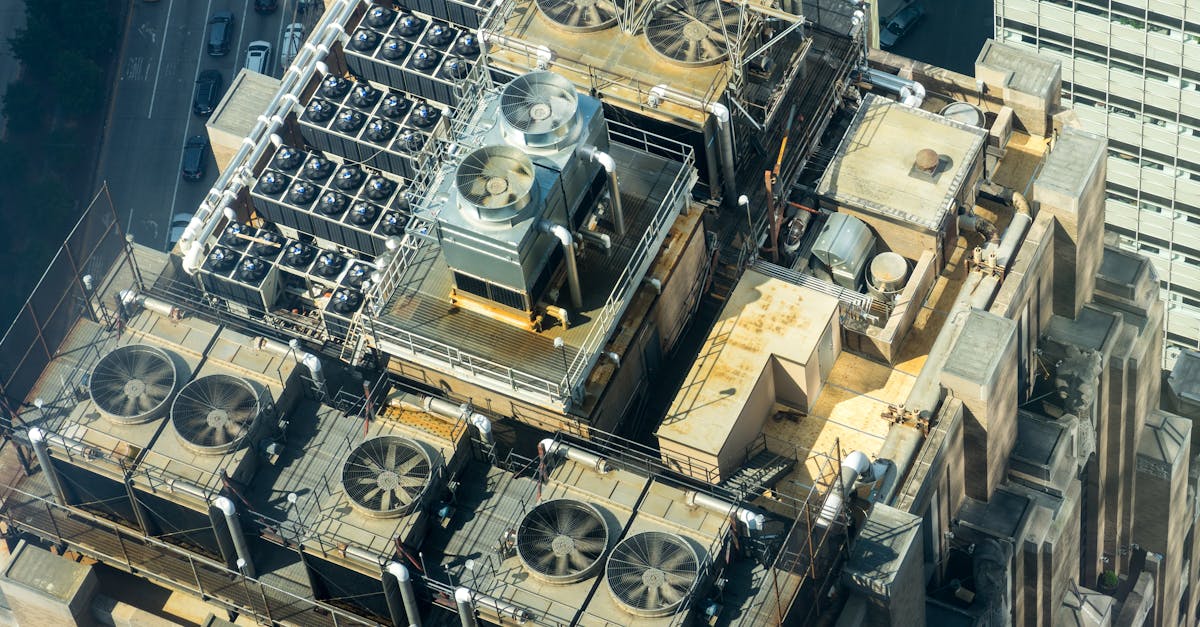

Coil Cleaning

When it comes to maintaining a heat pump system, one crucial step is ensuring that the coils are clean and free of debris. Clean evaporator and condenser coils are essential for efficient heat transfer within the unit. Over time, dirt, dust, and other contaminants can accumulate on the coils, hindering their ability to absorb and release heat effectively.

Regular maintenance of the coils not only helps in improving the heat pump's performance but also prolongs its lifespan. As part of routine heat pump maintenance, homeowners are advised to schedule professional coil cleaning services to ensure the system operates at its peak efficiency. Neglecting coil cleaning can lead to reduced heat pump efficiency, increased energy consumption, and potential malfunctions that may require costly repairs. Heat Pump Installation and Repair enthusiasts stress the importance of keeping the coils clean to maintain the system's overall functionality.

Clean evaporator and condenser coils to improve heat transfer

Clean evaporator and condenser coils play a crucial role in the efficiency of a heat pump system. Over time, dirt, dust, and grime can accumulate on these coils, hindering the transfer of heat. Regular cleaning of the coils is essential to ensure optimal performance of the heat pump. By keeping the evaporator and condenser coils clean, you can enhance heat transfer within the system, allowing it to operate more efficiently.

Heat pump installation and repair professionals recommend scheduling regular maintenance checks to inspect the condition of the coils. Cleaning the coils can be a simple task that can be performed by homeowners or HVAC technicians. This maintenance step not only improves heat transfer but also helps extend the overall lifespan of the heat pump system. Regular cleaning of the coils is a cost-effective way to ensure that your heat pump operates at peak performance levels.

Fan Motor Assessment

When it comes to the fan motor assessment in Heat Pump Installation and Repair, it is crucial to check the performance of the motor on a regular basis. Testing the fan motor's functionality is essential to ensure that it is operating efficiently. A malfunctioning fan motor can lead to decreased airflow and overall system performance.

In addition to testing the fan motor's performance, it is important to lubricate it if necessary. Proper lubrication can help reduce friction and wear on the motor, extending its lifespan. Regular maintenance of the fan motor will not only improve the efficiency of the heat pump system but also prevent costly repairs in the future.

Test fan motor performance and lubricate if needed

To ensure the efficient operation of a heat pump, it is essential to regularly inspect the fan motor for performance issues. Begin by turning off the power to the unit and visually inspect the motor for any signs of wear or damage. Next, gently spin the fan blades to check for smooth rotation. If there is any resistance or unusual noise, further testing may be required to pinpoint the problem.

After assessing the fan motor's functionality, it is recommended to lubricate it if needed. Adding lubrication can help reduce friction and prevent excessive wear on the motor components, ultimately prolonging its lifespan. Use a high-quality lubricant suitable for the motor type and apply it according to the manufacturer's guidelines. Proper maintenance of the fan motor is crucial for the overall performance of the heat pump system and should be included in routine maintenance procedures for Heat Pump Installation and Repair.

Pressure Gauge Testing

Pressure gauge testing plays a crucial role in diagnosing potential issues within a heat pump system. By using pressure gauges, technicians can assess the system's pressure levels to determine if they fall within the optimal range for efficient operation. This step is essential in the routine maintenance and troubleshooting of heat pump components to ensure they function effectively.

During the pressure gauge testing process, technicians should pay close attention to both the high and low-pressure readings indicated on the gauges. Discrepancies in these readings could suggest a leak, blockage, or other issues that may be impacting the system's performance. By conducting thorough pressure gauge testing as part of routine Heat Pump Installation and Repair procedures, technicians can proactively identify and address potential problems, helping to extend the lifespan of the heat pump and optimize its overall efficiency.

Use pressure gauges to evaluate system pressure levels

Use pressure gauges to evaluate system pressure levels in your heat pump to ensure optimal performance. Pressure gauge testing is a crucial step in diagnosing malfunctioning components as it provides valuable insights into the condition of the system. By comparing the pressure readings to the manufacturer's specifications, you can identify any abnormalities that may be causing issues with the heat pump.

Proper pressure gauge testing is a fundamental aspect of Heat Pump Installation and Repair. It allows you to assess whether the system is operating within the recommended pressure range, which is essential for efficient heat transfer. Monitoring the pressure levels regularly can help you detect any potential problems early on, preventing costly repairs down the line.

FAQS

How often should I clean the evaporator and condenser coils of my heat pump?

It is recommended to clean the evaporator and condenser coils of your heat pump at least once a year to improve heat transfer efficiency.

What are the signs that indicate a malfunctioning fan motor in a heat pump?

Signs of a malfunctioning fan motor in a heat pump may include unusual noises, reduced airflow, or the fan not spinning at the appropriate speed.

Can I test the performance of the fan motor in my heat pump myself?

Yes, you can test the performance of the fan motor in your heat pump by checking the speed, listening for any unusual noises, and ensuring that it is effectively circulating air.

How do pressure gauges help in diagnosing issues with a heat pump component?

Pressure gauges are used to evaluate the system pressure levels in a heat pump, which can indicate issues such as refrigerant leaks, blockages, or inefficiencies in heat transfer.

Is it necessary to lubricate the fan motor of a heat pump regularly?

It is recommended to lubricate the fan motor of a heat pump at least once a year to ensure smooth operation and prevent premature wear and tear.

Related Links

Heat Pump Installation and RepairRepairing a Damaged Heat Pump Compressor

Troubleshooting Issues with Heat Pump Evaporator Coils

Replacing a Faulty Heat Pump Condenser Coil

Fixing Problems with the Heat Pump Expansion Valve